EPE x ADURO part 2

The first half of the article here .

Outline of the article part 1 :

1) dimensional series

2) physical properties

3) biting part

- the situation

a) temperature drop in the pipeline

- calculation

- measurement outputs

- thermal camera outputs

4) the experience of our installers

b) coupling heat losses

We tested four types of connections that can be used to connect pipes and fittings in the size of 160 mm:

3) Spiro nipple

4) Spiro nipple insulated with 3mm synthetic rubber thermal tape

Each connection was photographed after 10 minutes to stabilize the conditions. Ambient temperature 7.5°C, pipe temperature 28.7°C.

1) EPE COUPLING (for EPE-EPE connection)

– material PP, with temperature factor. conductivity 0.2 W/mK

Result:

Our assessment :

If the clutch is properly installed, no leaks are visible on the camera. It is possible that after a longer period of time heat conduction will occur through the body of the PP coupling. In the case of suction, there could be a risk of condensation in extreme conditions (i.e. high humidity of the internal environment around the clutch) - can be secured with thermal tape. If the pipe is badly cut and does not reach the central ring in all places, the risk of condensation increases.

During development, the manufacturer must have thought of thermal bridges, because the connection of the inner and outer hem is only approx. 7 cm long.

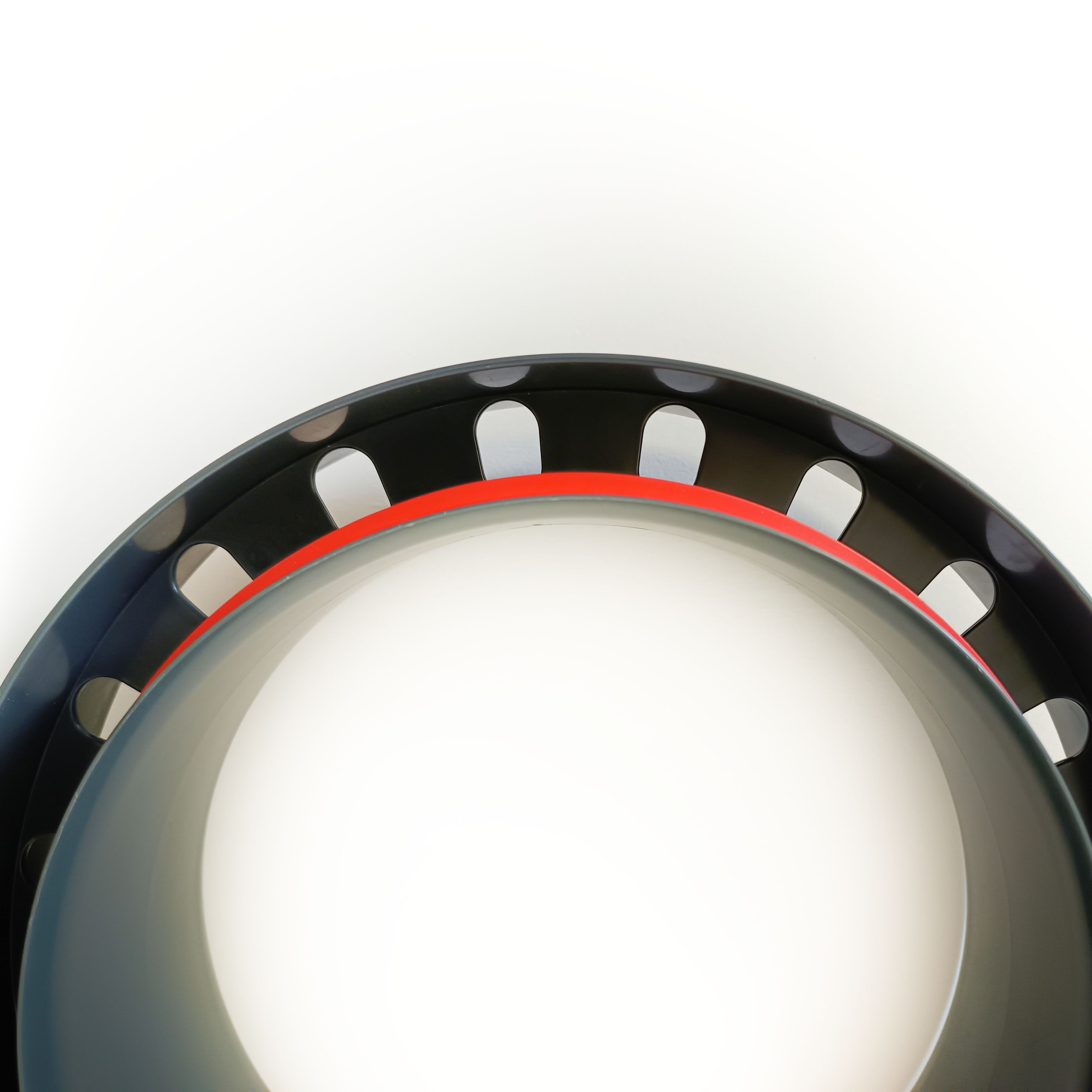

2) ADURO COUPLING (for connecting ADURO - ADURO)

– material PP, with temperature factor. conductivity 0.2 W/mK

Result:

Our assessment :

The rating is very similar to the EPE coupling - if the coupling is fitted correctly, no leaks are visible on the camera. With the ADURO coupling, the error rate of bad cutting and fitting with couplings is lower. And that's thanks to the stiffer material and lines on the surface that are 5 cm apart.

The center and outer rings are connected in the ADURO coupling, but the manufacturer tries to eliminate thermal bridges through holes in the structure.

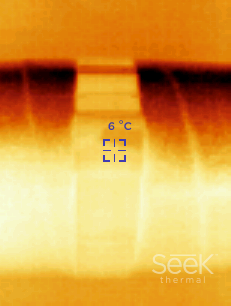

3) SPIRO COUPLING with VSG rubber (for EPE - EPE connection)

– material steel, with temperature factor. conductivity 17 W/mK

Result:

Our rating:

This connection is completely inappropriate. There are large heat losses and a high risk of condensation.

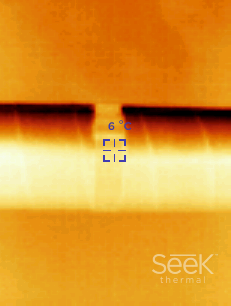

4) SPIRO COUPLING with VSG rubber (for EPE - EPE connection) + 3mm synthetic rubber tape

– material steel, with temperature factor. conductivity 17 W/mK + synthetic rubber, with temperature factor conductivity 0.036 W/mK, U = 3.95 Wm -2 .K -1

Result:

Our rating:

This connection can be used between components where it is not possible to use system connectors. We recommend insulating min. with two layers of tape or other insulation.

Our and technicians and installers answered questions about both systems and we created a so-called popularity chart. We also share our experience with both systems here.

Grading is like in school 1-5.

ASSEMBLER | Luke | Mario | Vojta | |||

System | EPE | ADURO | EPE | ADURO | EPE | ADURO |

Putting on clutches | 3 | 2 | 3 | 2 | 2 | 3 |

Pipe cutting | 3 | 1 | 2 | 1 | 3 | 1 |

Mooring | 2 | 3 | 2 | 3 | 2 | 2 |

Installation speed | 2 | 2 | 1 | 2 | 1 | 2 |

Biggest advantage | Long on the market, system roof headers | Lines for cutting, better cleanability with brushes | Ease of assembly | The assurance of a tight connection | Flexibility, allows an error of a few cm when connecting the unit | A solid surface that won't be easily damaged on the construction site. Suitable for penetrations. |

The biggest drawback | Soft material on the surface | Absolute measurement accuracy is required | Possibility of damage in penetrations | It has not been tested for a long time, on the Czech market only in the order of months (evaluated 2/22) | It is not always easy to make a straight cut. Soft surface. | More difficult sliding of clutches in inaccessible places |

EPE:

it has worse thermal insulation properties, but it is a more flexible material that forgives minor errors in measurement (e.g. when connecting the unit). It has a wide range of components and a tradition in the market. Its surface is softer than ADURA and is prone to damage from sharp edges.

ADURO:

It has a solid wall with better thermal insulation properties. Without much clearance during assembly, everything must be very precise, then its installation will bring very high quality results.

Both systems are of high quality and the differences between them are more in the developers' conception of causes than in the actual result, so we can warmly recommend them both.

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)