What pipes for the recovery system?

WHICH AIR DUCT (PIPE DISTRIBUTION) SYSTEM TO CHOOSE?

Material, hygiene (mold, bacteria, ...), pressure losses, cleaning possibilities, noise conduction, crosstalk, etc. are decisive factors.

What matters...

The basic question is which recuperation system you choose. If passive, which we highly recommend, then you can run the air supply and exhaust pipes through the floor, ceiling and walls.

Depending on the spatial possibilities of the building, the size of the pipe and the related material will be chosen. It also depends on your requirements for hygiene, acoustics, etc.

The amount of materials for conducting air in family houses is increasing, so we have prepared a basic overview of what to expect from individual types of pipes. The overview table expresses our personal experience with individual materials that we collected during our practice.

It can be seen from the above table that the current leader in materials for air distribution in family houses are double-walled plastic pipes with an internal hygienic insert that contains additives. Thanks to these ingredients, the protection is not only antibacterial, anti-fungal, anti-algae and anti-fungal, but also protects against microbes and E. coli. The new materials are also antistatic.

Further distribution of pipelines for recuperation for inlet and outlet:

A) PLASTIC PIPE SYSTEM OUTSIDE DIMENSIONS 75 and 90 mm

B) BRANCHED SYSTEM - SPIRO, SONO, MULTIPLAST, SQUARE GALVANIZED

A) PLASTIC PIPE SYSTEM OUTSIDE DIMENSIONS 75 and 90 mm

REFERRED TO AS A DISTRIBUTOR OR STAR SYSTEM

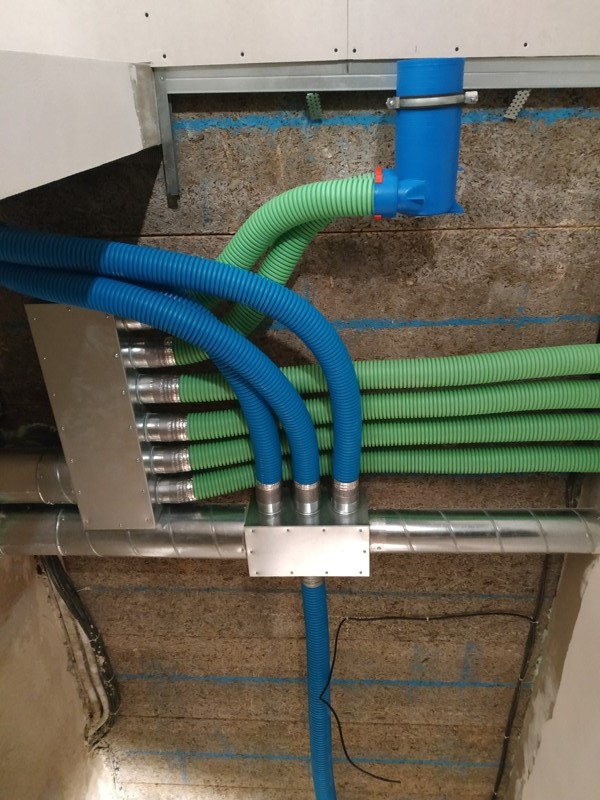

From the unit, the air is led to the occupied rooms usually through a flexible silencer and through the SPIRO pipe to the distribution (=distribution, distribution) box . This distribution box divides the air into individual plastic pipes with an outer diameter of 75 mm or 90 mm .

We make distribution boxes to measure (ATYP) based on the number of hoses and the space in which the box is located, or we use mass-produced boxes. The box usually includes a service hole and antibacterial noise insulation. Thanks to the so-called star piping solution and noise-absorbing material, noise does not spread through the piping from room to room. From a service point of view, the box is a central hub that needs access for cleaning.

ZINC DISTRIBUTION BOX (TYPE OR SERIES PRODUCTION):

DISTRIBUTION BOX MADE OF ALP MATERIAL - THERMALLY INSULATED (TYPE OR SERIES PRODUCTION):

PLASTIC DISTRIBUTION BOX (MODIFIABLE, SERIES PRODUCTION):

More about sytem 75mm, 90mm (plastic air duct)

The 75 and 90 mm system is a modern flexible system for air distribution that we have been using on our installations for more than 8 years with the following advantages:

- Very simple design and quick installation thanks to the radially flexible structure of endless pipe laying directly from the roll - saving approx. 2/3 of the time required for classic installation from a fixed pipe.

- Up to 50% fewer components required for assembly compared to other systems.

- High stiffness of circular pipes (problem-free placement in concrete, high resistance to mechanical damage).

- Quick commissioning due to minimal requirements for regulating the system.

- Uniform air distribution.

- The beam-shaped system without fittings allows for easy cleaning.

- Max. branch flow for basic system design diameter 90 mm - 40 m3/hour, diameter 75 mm 30 m3/hour

- Recommended maximum pipe length 15 m (straight).

Pipes: We sell both pipe diameters in HYGIENIC design (green and white).

Advantages of the HYGIENIC pipeline: The inner wall of the pipeline is provided with antibacterial, antifungal and some antistatic admixtures, which ensures hygienic protection against bacteria and fungi.

The 90 mm pipe will bring you more air with lower noise and less pressure loss. Other parameters are the same.

The plastic pipe is usually terminated with a ceiling box , into which a distribution element (outlet) is inserted in the second phase of installation.

We select ceiling boxes according to:

- suitability of anchoring (to the supporting structure, anchoring to plasterboard)

- required tube lengths (according to the height of the installation gap)

- according to the number of connected hoses (1-2-3)

We sell boxes in PLASTIC and POLYZINC versions, metal boxes usually contain a noise lining.

Ceiling boxes 90 mm - Ceiling boxes 75 mm

B) BRANCHED SYSTEM - SPIRO (SONO, MULTIPLAST, SQUARE GALVANIZED)

This is a traditional system where 3m long SPIRO pipes are shortened and connected by a system of fittings with rubber seals . We use the system in larger houses where the routes exceed 15 m or where there is no installation gap under the ceiling and the pipes must be hidden in boxes (false beams).

This system is often used in industry and other sectors where larger flow rates and diameters are required. As a ventilation solution with recuperation, its popularity has recently been declining a bit.

The following parameters are problematic, which often lead to changing the system to 75 mm or 90 mm:

- crosstalk (noise spreads unchecked from room to room with this system, the use of crosstalk silencers is limited due to cleaning and pressure losses)

- high built-in height for circular cross-sections / the pipe itself has a diameter of 125 mm or 160 mm+ in family houses, it requires space for anchoring and longer fittings for outlets)

- difficult to clean with this system, the fittings are usually connected to the pipe using screws. When cleaning the system, these screws are a source of problems. In addition, each joint increases the risk of accumulation of dust etc. in the pipeline.

- regulation - can be ensured using flaps, to which, however, access is necessary - i.e. service hole (eg) in the ceiling

Detail informations

we use it at least, for example, for flexible lines in technical areas, where pipes can be replaced instead of cleaned

WHITE PLASTIC SYSTEM /UNIPLAST, MULTIPLAST ETC./

we sometimes use it in combination with SPIRE for smaller dimensions of fittings

SQUARE PIPE SYSTEM: on request

we use it in very exceptional cases where it is necessary to minimize the height of the pipes, usually to the floors

THE ARTICLE WAS UPDATED ON 4/8/2020

Ing. Pavla Skalická